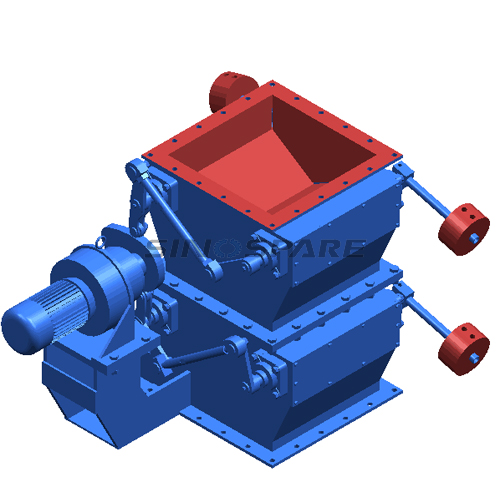

Rotary Airlock Valve for Cement Plant

Key Specifications / Features

Model No.: VAG-03 Hits: 316

Cement rotary airlock valve supplier in China provides customized rotary airlock valves for powdery and granular materials conveying in cement plant.

Request a quote

Share

Tags:

Detail Infomation

The rotary airlock valve can be used in the material collection system as an unloader of the silo or collector. The rotary valve is the most advanced unloading device in material handling system of industry plants and commonly used as one of the most important equipment of the dust removal system in the dust collecting system.

The rotary airlock valve commonly used in positive pressure or negative pressure output system inpneumatic conveying system. The rotary airlock valve can uniformly and continuously feed materials and ensure that the gas and solid in the pneumatic conveying system are relatively stable because the upper and lower air pressures of rotary airlock valve are blocked, and the pneumatic conveying can work normally.

SINOSAPRE offers the following types of rotary valve for different choices:

• The upper and lower flanges of the rotary valve are basically square or round, A is square, B is round. All types of rotary valve can be customized.

• Rotary valves mainly include motor, gear reducer (X) or cycloidal reducer (Z) and rotary impeller.

• Wear-resistant rotary valve are with Teflon sealing strip on the rotary blade so as to enhance the joint between blade and inner shell of rotary valve which results in better sealing performance.

• High-temperature resistance rotary valve equipped with sprocket drive to separate reducer and rotary. Furthermore, the additional distance between the rotor and bearing are made for temperature resistance purpose. The high-temperature resistance rotary valve can handle the material with temperature up to 600℃.

FEATURES & BENEFITS

• Smooth and Reliable Performance

• Balance and Accurate Discharge

• Optimized Structure

• Small Size

• Good Sealing Performance

• Convenient Maintenance

• Light and Energy Saving

• Long Service Life

• Low Noise

APPLICATION

Rotary Valve is suitable for pneumatic conveying of powdery materials and granular materials.

SPECIFICATION

The rotary airlock valve commonly used in positive pressure or negative pressure output system inpneumatic conveying system. The rotary airlock valve can uniformly and continuously feed materials and ensure that the gas and solid in the pneumatic conveying system are relatively stable because the upper and lower air pressures of rotary airlock valve are blocked, and the pneumatic conveying can work normally.

SINOSAPRE offers the following types of rotary valve for different choices:

• The upper and lower flanges of the rotary valve are basically square or round, A is square, B is round. All types of rotary valve can be customized.

• Rotary valves mainly include motor, gear reducer (X) or cycloidal reducer (Z) and rotary impeller.

• Wear-resistant rotary valve are with Teflon sealing strip on the rotary blade so as to enhance the joint between blade and inner shell of rotary valve which results in better sealing performance.

• High-temperature resistance rotary valve equipped with sprocket drive to separate reducer and rotary. Furthermore, the additional distance between the rotor and bearing are made for temperature resistance purpose. The high-temperature resistance rotary valve can handle the material with temperature up to 600℃.

FEATURES & BENEFITS

• Smooth and Reliable Performance

• Balance and Accurate Discharge

• Optimized Structure

• Small Size

• Good Sealing Performance

• Convenient Maintenance

• Light and Energy Saving

• Long Service Life

• Low Noise

APPLICATION

Rotary Valve is suitable for pneumatic conveying of powdery materials and granular materials.

SPECIFICATION

| MODEL | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 26 | 30 | 40 | 50 | |

| CAPACITY (litres/r) | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 26 | 30 | 40 | 50 | |

| SPEED(r/min) | 25~40 | ||||||||||||||

| WORKING TEMPERATURE | T≤ 80℃, T≤ 200℃ | ||||||||||||||

| MATERIAL | POWDER, GRANULES MATERIAL | ||||||||||||||

| MOTOR | MODEL | Y801-4 | Y802-4 | Y90S-4 | Y90L-4 | Y100L1-4 | Y100L1-4 | Y112M-4 | Y132S-4 | ||||||

| POWER (KW) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | |||||||

| SPEED (r/min) | 1390 | 1400 | 1430 | 1430 | 1430 | ||||||||||

| WEIGHT(Kg) | 53 | 71 | 86 | 101 | 121 | 141 | 161 | 181 | 191 | 221 | 251 | 301 | 491 | 681 | |

| DIMENSIONS (mm) | |||||||||||||||

| TYPE | Outer Diameter | Inner Diameter | Height | Pitch | Bore Diameter | Motor Power (KW) | |||||||||

| YJD02 | 250 | 150 | 225 | 200 | 8-Ф9 | 0.55 | |||||||||

| YJD04 | 280 | 180 | 280 | 230 | 8-Ф11 | 0.75 | |||||||||

| YJD06 | 300 | 200 | 300 | 250 | 8-Ф11 | 0.75 | |||||||||

| YJD08 | 320 | 220 | 320 | 270 | 8-Ф11 | 0.75 | |||||||||

| YJD10 | 340 | 240 | 340 | 290 | 8-Ф13 | 1.1 | |||||||||

| YJD12 | 360 | 260 | 360 | 310 | 8-Ф13 | 1.1 | |||||||||

| YJD14 | 380 | 280 | 380 | 330 | 8-Ф17 | 1.1 | |||||||||

| YJD16 | 400 | 300 | 400 | 350 | 8-Ф17 | 1.5 | |||||||||

| YJD18 | 420 | 320 | 440 | 370 | 8-Ф17 | 1.5 | |||||||||

| YJD20 | 440 | 340 | 450 | 390 | 8-Ф17 | 1.5 | |||||||||

| YJD26 | 500 | 400 | 50 | 450 | 8-Ф17 | 2.2 | |||||||||

| YJD30 | 550 | 440 | 560 | 490 | 12-Ф17 | 3 | |||||||||

| YJD36 | 610 | 500 | 630 | 560 | 12-Ф17 | 3 | |||||||||