Side Scraper Reclaimer for Cement Plant

Key Specifications / Features

Model No.: SAR-03 Hits: 326

China side scraper reclaimer supplier provides custom side scraper reclaimer for cement plant, fully automatic operation, preset protection program.

Request a quote

Share

Tags:

Detail Information

General Information

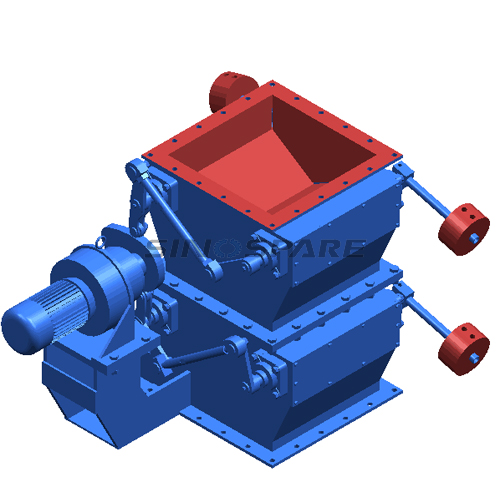

The side cantilever scraper reclaimer is the most economical solution for the small open-air stack yard with the advantage of flexible and lightweight. It travels on a track installed along one side of the stockyard and features a boom with double strand chain and scraper blades. The side cantilever scraper reclaimer is widely used in material handling sector in heavy industry production line, such as cement, coal, electric power, metallurgical, steel, chemical plant.

Basic Structure

The side cantilever scraper reclaimer mainly consists of walking beam, rack, winch system, scraper reclaimer system, carriage, lubrication system, rail system, control room, etc.

Technical Characteristics

1.Perfect homogenization

In the longitudinal material blending yard, different stacking processes can be adopted according to different working conditions. Continuous synthetic stacking methods can be adopted to ensure the homogenization effect in the circular material blending yard.

2. Reliability

2.1 We guarantee the advanced and reasonable technology and stable equipment with the experience and development of making stackers and reclaimers as well as absorbing the advanced technology from international.

2.2 Advanced production equipment and manufacturing technique, such as steel pretreatment line which improves the product's quality and anti-corrosion capability, large milling and boring machine improves quality of large parts. Large-scale structural components processed the pre-assembling procedure driving parts we will be tested before delivery. Rotating parts are all processing mold integrated manufacturing.

2.3 New materials applicating, such as wear-resistance material, composite material.

2.4 First class quality fittings.

2.5 Damage reduced by soft start and frequency converting control.

2.6 Protection programs are presetting

2.7 Advanced testing methods and QC system in our plant.

3. Advancement

3.1 Fully automatic operation.

3.2 Various stacking and reclaiming methods presetting to satisfy different work condition of blending yard.

3.3 Advanced frequency conversion technical.

The side cantilever scraper reclaimer is the most economical solution for the small open-air stack yard with the advantage of flexible and lightweight. It travels on a track installed along one side of the stockyard and features a boom with double strand chain and scraper blades. The side cantilever scraper reclaimer is widely used in material handling sector in heavy industry production line, such as cement, coal, electric power, metallurgical, steel, chemical plant.

Basic Structure

The side cantilever scraper reclaimer mainly consists of walking beam, rack, winch system, scraper reclaimer system, carriage, lubrication system, rail system, control room, etc.

Technical Characteristics

1.Perfect homogenization

In the longitudinal material blending yard, different stacking processes can be adopted according to different working conditions. Continuous synthetic stacking methods can be adopted to ensure the homogenization effect in the circular material blending yard.

2. Reliability

2.1 We guarantee the advanced and reasonable technology and stable equipment with the experience and development of making stackers and reclaimers as well as absorbing the advanced technology from international.

2.2 Advanced production equipment and manufacturing technique, such as steel pretreatment line which improves the product's quality and anti-corrosion capability, large milling and boring machine improves quality of large parts. Large-scale structural components processed the pre-assembling procedure driving parts we will be tested before delivery. Rotating parts are all processing mold integrated manufacturing.

2.3 New materials applicating, such as wear-resistance material, composite material.

2.4 First class quality fittings.

2.5 Damage reduced by soft start and frequency converting control.

2.6 Protection programs are presetting

2.7 Advanced testing methods and QC system in our plant.

3. Advancement

3.1 Fully automatic operation.

3.2 Various stacking and reclaiming methods presetting to satisfy different work condition of blending yard.

3.3 Advanced frequency conversion technical.

| Main Technical Parameters | |

| Taking Material | Coal,Lime Stone,Auxiliary Material |

| Capacity | 1.45t/m3,0.85t/m3,1.2t/m3 |

| Material Taking Capability | 50t/h,100t/h,150t/h,200t/h,250t/h,300t/h,400t/h,500t/h,750t/h,1000t/h,1200t/h,1500t/h,1800t/h,2000t/h |

| Cantilever length | 12m,14m,16m,18m,20m,22m,25m,28m,30m |

| Taking speed | 0.2~2m/min |

| Walking Speed | 10m/min |

| Rolling Speed | 2.42m/min~24.2m/min |

| Scarper Speed | 0.41m/s |

| Rail Gauge | 4m,5m |